α-phe AIMS (Asset Integrity Management System) is a software system used for managing and maintaining the integrity of assets, such as pressure vessels, piping’s, pipelines, tanks, and other equipment. A key feature of α-phe AIMS is the ability to record and manage data related to the condition of assets, including wall thickness measurements.

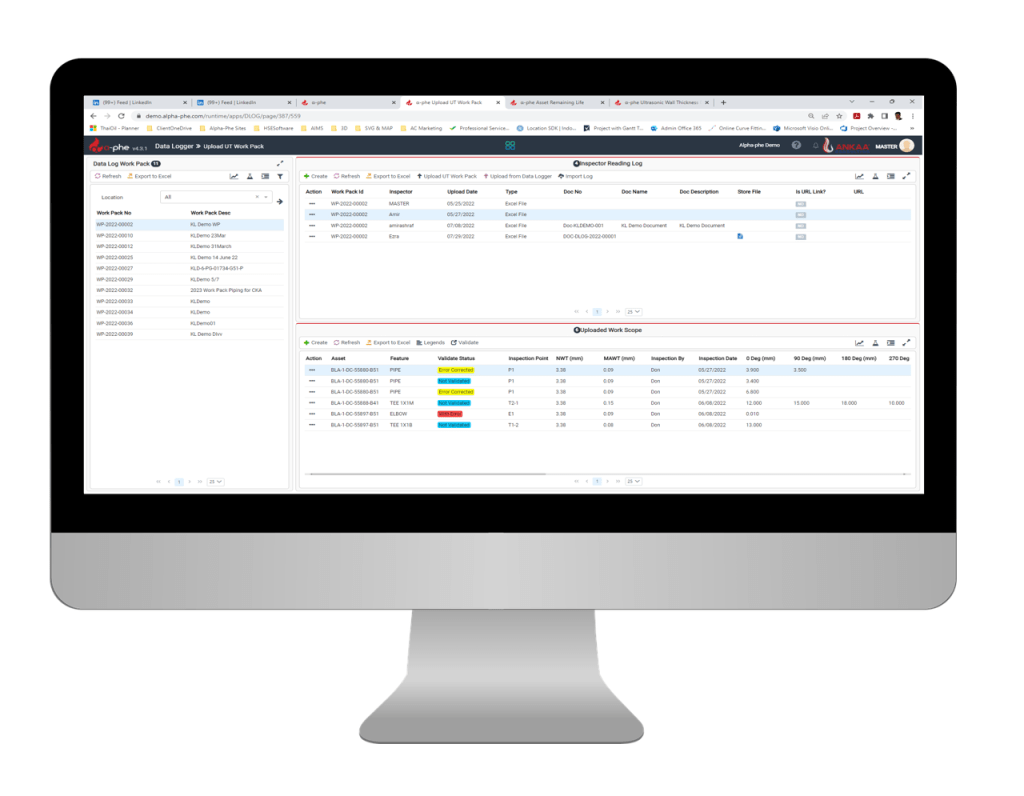

Ultrasonic wall thickness data collected using UT data loggers can record multiple test points in a single work pack. This can simplify the inspection process and reduce the potential for errors, as multiple readings can be taken quickly and accurately at various locations.

The α-phe AIMS software system can facilitate this process by allowing the scope of work to be downloaded from the work pack module, which specifies the specific locations and parameters for the inspection. The data collected using the UT data loggers can then be uploaded back into the α-phe AIMS software system for quality assurance and quality control checks before being used for any analysis.

The α-phe AIMS software system can perform various quality assurance and quality control checks, such as verifying that the collected data meets the required specifications and identifying any outliers or errors in the data. This can ensure that the data is accurate and reliable, which is important for making informed decisions about asset maintenance and repair.

The QA/QC checks performed by α-phe AIMS may include various data validation techniques, such as range checks, consistency checks, and statistical analysis. This helps to identify and correct any errors or outliers in the data before it is used for advanced assessments.

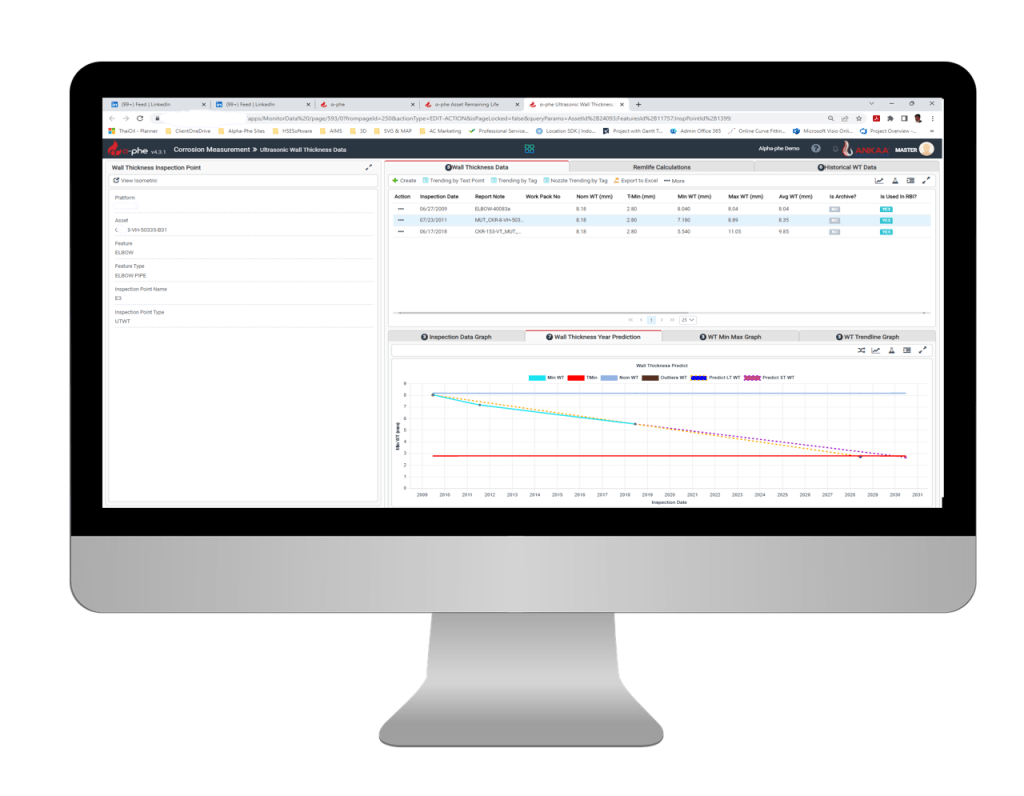

The good data collected will be used forthe future trending requirements, to perform risk based inspection assessment and further inspection planning process. A long term and short term corrosion rate is calculated, which is used for deriving the remaining life and next inspection due date for each test points. A more optimized inspection plan for next round of inspection can be derived using this these information’s.

The ability to record and manage wall thickness data in α-phe AIMS, use of data loggers along with its built-in QA/QC checks, can help to ensure the safe and reliable operation of assets over their entire lifecycle.