Ankaa Consulting – Pioneering Precision in Plant Safety and Efficiency.

At Ankaa Consulting, we specialize in providing comprehensive Risk-Based Inspection services tailored to meet the unique needs of both new and existing plants in the oil, gas, and petrochemical industries. Our systematic approach, rooted in the best practices outlined in API 580 and 581, is designed to enhance the safety, reliability, and efficiency of your operations.

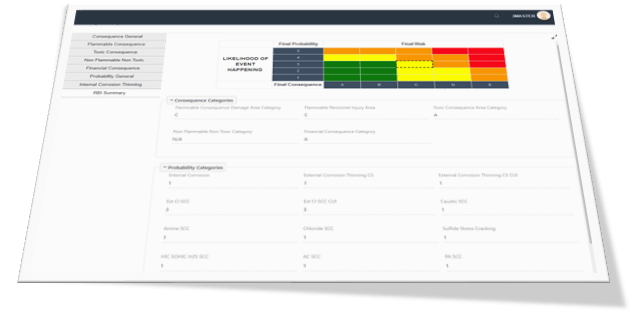

α-phe RBI Software Solution

When developing an Risk Based Inspection (RBI) scheme for an asset, we adopt a two stage approach. Initial risk is determined utilising a qualitative or semi-quantitative approach. High risk items identified after this stage are then subjected to a quantitative risk assessment to greater refine the calculated risk. This approach offers a highly cost effective approach for the risk determination and inspection planning process.

Items with a high risk are given a higher priority for inspection while medium and low risk items are given a lower priority. This is achieved by relating the level of risk calculated to required inspection intervals.

RBI assists a company to select cost effective and appropriate maintenance and inspection tasks and techniques, to minimize efforts and cost, to shift from a reactive to a proactive maintenance regime, to produce an auditable system, to give an agreed “operating window”, and to implement a risk management tool.

The benefits of RBI include:

- To provide a holistic, interdependent approach for managing risk

- Identification of equipment operational risks through identification of their failure mechanisms.

- To apply a strategy of doing what is needed for safeguarding integrity and improving reliability and availability of the asset by planning and executing those inspections that are needed

- To reduce inspections and shutdowns and increase plant availability without compromising safety or reliability

- To safeguard integrity and reduce the risk of failures

- To provide a dynamic system that continuously improves and adapts to changing risks

- To ensure inspection techniques and methods consider potential failure modes

- To reduce inspections for low risk items allowing costs to be optimised more appropriately to high risk items.

Our RBI Approach

- Initial Assessment and Planning

- Understanding Your Needs: We begin with a thorough assessment of your plant’s specific requirements, considering both operational and regulatory aspects.

- Customized RBI Program Design: Based on the initial assessment, we design an RBI program that aligns with API 580 and 581 standards and integrates seamlessly into your existing processes.

- Data Collection and Analysis

- Comprehensive Data Gathering: We collect and analyze data on your equipment’s condition, operating environment, and historical performance.

- Risk Assessment: Utilizing advanced analytical tools, we evaluate the probability and consequence of failure (PoF and CoF) for each equipment component.

- Strategic Inspection Planning

- Prioritized Inspection Schedules: Our RBI strategy prioritizes inspections based on risk, ensuring optimal allocation of resources and maximizing safety.

- Advanced Inspection Techniques: We employ cutting-edge inspection technologies to accurately assess the integrity of your assets.

- Implementation and Monitoring

- Seamless Implementation: Our team of experts ensures a smooth implementation of the RBI program, minimizing disruption to your operations.

- Continuous Monitoring / Reassessment: We provide ongoing monitoring and support, adjusting strategies as needed to reflect operational changes or new data.

- Reporting and Compliance

- Detailed Reporting: Receive comprehensive reports with actionable insights, helping you make informed decisions about maintenance and operations.

- Regulatory Compliance: Ensure full compliance with industry standards and regulations, including API 581.

Bespoke Solutions for Unique Challenges

We recognize that each plant has its unique challenges. That’s why, beyond standard API 581 implementations, we offer bespoke solutions tailored to your specific needs. Our team works closely with you to develop custom strategies that address your unique risk factors and operational goals.

Partner with Ankaa Consulting

- Expert Team: Our team comprises seasoned industry professionals with deep expertise in RBI methodologies.

- Client-Centric Approach: We pride ourselves on a client-centric approach, ensuring solutions that are not only compliant but also practical and cost-effective.

- Commitment to Excellence: At Ankaa Consulting, our commitment to excellence is unwavering. We continuously update our methods and knowledge to stay at the forefront of RBI technology and practices.

Contact Us Today

Ready to elevate your plant’s safety and efficiency with a tailored RBI program? Contact Ankaa Consulting today to discuss how we can support your objectives.